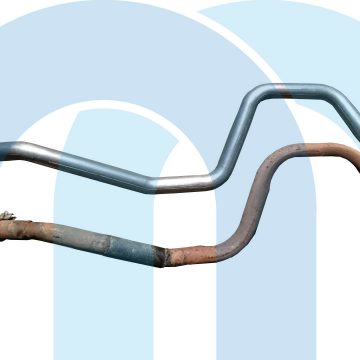

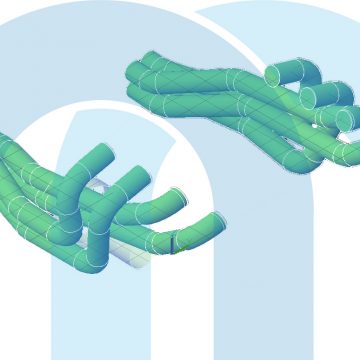

State of the art 3D Scanning technology allows us to replicate supplied samples with complete accuracy. This technology enables us to transform a single piece of wire into a concise custom tube bend. Items scanned can be programmed into our mandrel benders for repeat orders. Our 3D Scanner uses non-contact tube probes, this enables us to measure tube and bend angles, while standard touch probes ensure that full tube assemblies – including any welded fixtures like brackets or hangers – can be measured.